by Daniel Hillin (July 2019)

When are the grapes going to be ready to harvest? Well, it depends…

Harvest determination is often a tricky subject here in Texas. Ripening grapes encompasses many different variables that change year to year depending on the weather and location. Our hot, unpredictable climate can lead to rapid changes in berry development and expedited harvest. Unpredictable weather can bring hail damage to the High Plains and flooding to the lower Rio Grande Valley all in the same growing season. Texas is so large and diverse that the difference in harvest date can vary as much as four months between specific regions. These unique challenges require close monitoring by producers on a year to year basis. This article will review the changes that occur during grape berry ripening and cover specific berry sampling procedures that can help growers closely monitor the ripening process right up to harvest.

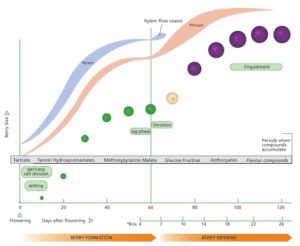

Grape berry development is typically characterized by three distinct stages of growth: the first stage of growth, beginning at berry set, results primarily from cell division. During this stage, organic acids accumulate in addition to other compounds that make the berries unpalatable and unattractive to animals. During the second stage, known as lag phase, the seeds inside berries mature and become viable. Otherwise, berry growth is not visible. The final stage (stage III) of growth, ripening, begins with veraison.

Veraison typically refers to a population of berries in a cluster, shoot, vine, row, block, or vineyard where 50% of the berries have changed color. In addition to berries changing color, several other physiological processes take place during the ripening period including:

- Berry softening and expansion

- Sugar accumulation

- Acidity variation

- Color change in the skin

- Flavor and aroma compound development

Berry softening and sugar accumulation begin simultaneously at the onset of ripening, followed by berry expansion and skin color development. Green chlorophyll molecules in the skin degrade and anthocyanin (color pigments) levels and berry pH increase during the ripening process. Seeds change color from green to brown, and multitude of different flavor and aroma compounds are synthesized and transformed all prior to harvest.

Figure 1. General representation of berry development and maturation. Kennedy, J. (2002).

Berry Softening and Expansion

Berries begin to soften and expand to allow for more water and sugar to accumulate. During this expansion, the mesocarp (pulp) cell walls are degraded to a point where they become more flexible allowing them to expand with the increased amount of water deposited into the mesocarp cell vacuoles (storage compartments within the cell). During ripening and expansion, water makes up about 70 – 80% of the berry weight. Sugars and other dissolved solids also play a role in allowing for an increase in the amount of water each berry can amass. In our hot Texas climate, too much water near harvest, usually in the form of a heavy rainfall, can result in berry swelling to a point where the skin ruptures. These cracks, even ones not visible to the human eye, during any point of the growing/ripening process can allow for bunch rot organisms such as acetobacter to enter and rot the berries.

Sugar Accumulation

A major physiological change that occurs at veraison, responsible for the increase in sugar accumulation in the berry, is the change in the primary transport path of water, carbohydrates, and nutrients from the xylem to the phloem (Figure 1). The xylem is the conductive tissue that moves water from the roots throughout the plant and the phloem is responsible for moving carbohydrate energy produced by the leaves around. With this change, the phloem transport allows for the greater accumulation of amino acids and carbohydrates. Glucose and fructose are the two principle sugars in grape berries, making up 95 to 99% of the sugar present in the berries. The amount of sugar stored at harvest is proportional to potential alcohol. Winemakers estimate potential alcohol by multiplying percent soluble solids or °Brix times 0.5. Here in the hot climate of Texas, soluble solids levels can rise very rapidly, as was observed in 2018. The hot, dry summer weather resulted in rapid sugar accumulation in many vineyards expediting harvest.

Acidity Variation

After veraison and throughout berry ripening, the pH within the berry increases and in turn, the titratable acidity (TA) decreases. Tartaric (tartrate) and malic acid (malate), the principle acids accounting for about 90% of the acids in grapes, are synthesized in the berry from berry set to after lag phase (Figure 1). Tartrate levels are generally consistent after veraison but can be reduced due to rain at harvest time or increased slightly due to berry dehydration from lack of moisture. Malate levels continue to decrease during maturation due to respiration, which can be accelerated by high temperatures. Respiration occurs nonstop during the day and the night, and our warm summer nights represent one of the climatic differences between Texas and areas of the west coast where the Pacific Ocean has a strong influence on temperature.

Monitoring acidity during the ripening phase is essential to ensure that the desired acid level is achieved at harvest. Problems associated with high pH can include increased risk potential for oxidation, unwanted microbial activity, poor color retention in red wines, and/or “flat” unbalanced wines with elevated pH and shorter shelf lives. The ideal textbook pH for wines is about 3.0. However, Texas grapes have often higher pH, sometimes reaching 4.0 or more. While in many cases, this may not be avoided, it is critical to track acid levels in ripening fruit to hit chemistry targets.

Color Change

Color change in the skin of the berries is brought about by the development and accumulation of flavonoids. Flavonoids are a very diverse group of compounds produced by complex metabolic pathways within the vine. Flavonols, tannins, and anthocyanins are three classes of flavonoids in grapes that have great influence on wine structure and quality. All three are important for the color and astringency of red wine, contribute to wine flavor and aroma, and are the main substrates for juice and wine oxidation.

- Flavonols – these compounds are located within the skin of the berry and are present at much lower concentrations than tannins and anthocyanins. They provide protection from harmful UVB radiation which is why they occur in higher concentrations in sun exposed grapes rather than shaded grapes. Due to this “sunscreen” role, flavonol concentration can fluctuate greatly between the sun exposed and shaded sides of each cluster within the canopy due to differing amounts of sun exposure. In wine, flavonols can be perceived as bitter, and they play an important role in initial color stabilization of red wines.

- Tannins – these compounds are produced in the seeds and skins of the berry. Tannins in grape juice and wine are responsible for the “drying” feeling on the tongue or “texture” in the grape juice or wine. They also play a role in color stability. Oxidation of the tannins produced on the seed coat during ripening causes the seeds to turn brown. This color change along with the taste and mouthfeel of the grapes is an excellent indicator of tannin concentration and overall grape maturity prior to harvest.

- Anthocyanins – these are the red, blue, and purple pigmented compounds responsible for the various colors that occur in the skins of different grape varieties. At veraison, the color change that occurs is due to the simultaneous breakdown of chlorophyll and accumulation of anthocyanins in the skin of the berries. This process begins to take place after the onset of sugar accumulation and berry softening, and after tannin accumulation in the berry skin has mostly finished. Temperature and light exposure are the two main environmental factor that have the greatest influence on anthocyanin formation and/or degradation. While light exposure plays a role in anthocyanin development in some grapes, temperature has a greater impact on anthocyanin concentration.

Flavor and Aroma Compounds Development

Grapes produce many different flavor compounds that are perceived in wine. There is no single compound responsible for either flavor or aroma. Several different flavor and aroma compounds exist across a multitude of grape varieties. Many of these compounds are unique and distinguishable by grape variety such as citrus aromas in Muscat varieties. Varietal character flavor and aroma compounds are derived from many different secondary metabolites and develop during the more advanced stages of ripening. High day and night temperatures during the Texas summer can severely hinder the ability of certain grape varieties to produce some of the more desired complex flavor and aroma compounds.

BERRY SAMPLING

Considering the complexity of maturation and rapid changes that often occur, deciding when to harvest grapes can be one of the most daunting decisions producers face on a yearly basis. Berry sampling for fruit maturity after veraison and up to harvest is one of the best techniques that growers have to monitor and track for crop maturity. Grape quality parameters agreed upon between the grape producer and the wineries are the foundation for management decisions made throughout this period of the year.

Berry Sampling Technique

Sampling berries periodically throughout the development stage between veraison and harvest allows producers to track the ripening process. Grape ripening is influenced by numerous factors and will vary between varieties, locations, and years. Beginning after full veraison, berry samples should be collected every 7-10 days, 3-5 weeks prior to harvest. Sampling frequency may need to increase to every 2-3 days in the 10-day period leading up to the predicted harvest date. The record keeping of this data from individual variety blocks all the way up to the entire vineyard will provide a reference for future years, especially if the data from that vineyard or block is followed through the winemaking process. Generally, a 200-berry sample is enough to give an accurate representation for +/- 1 °Brix, or a 500-berry sample can be taken for +/- 0.5 °Brix. Samples should be collected before 10:00 AM and should come from vines that are randomly selected and that are representative of the plot. Take care to avoid sampling end-row vines and from outside rows. When picking berries, randomly select one berry per cluster from the top, middle, and bottom, as well as front and back. Select 5 berries per cluster and only select from one cluster per vine. Also, pick berries from both sides of vertical canopies reaching through the foliage to select berries with varying degrees of sun exposure. Once collected, berries should be placed in plastic bags and crushed thoroughly, ideally to the same extent that will be done by the press at the winery. The juice should be removed and decanted for several hours to allow particulates to settle to the bottom. Once this has occurred, the juice is ready to be measured via refractometer. The same juice can be used to test pH and titratable acidity if you are equipped to take these measurements. Remember to record the sample information, test results, who sampled, vineyard block, variety and date and time of collection for future reference and comparison.

Measurements of Maturity and Quality

Most often producers rely on three different measurements to asses grape maturity and potential wine quality. Soluble solids (sugar), pH, and titratable acidity are all useful in describing the degree of grape maturity for when to harvest. These measurements do not paint the entire picture of the grape ripening process, but they are effective tools that can give growers a better understanding of where their fruit is in this process.

- Sugar concentration – commonly referred to as degrees Brix (°Brix) is a common industry measurement that is easy to take. Sugar concentration in the berry has a large impact on fruit quality and alcohol potential during fermentation. Sugar concentration in grapes is generally measured by both grape producers and winemakers with a refractometer. It should be noted that the temperature of the solution tested must be at 20°C or 68°F. Deviations in temperature below and above 20°C will cause variation in the °Brix reading due to the density of the solution. Differences in solution temperature will require correction for a more accurate reading.

- pH – pH is an expression of acidity or alkalinity in a solution, utilizing a scale where 7.0 is neutral, lower values are acidic and higher values are alkaline. One factor that can cause an increase in the pH is the concentration of Potassium (K+) which tends to counter the influence of organic acids by substituting for H+ and effectively raising the overall pH. The ability of the juice pH within the berry to be influenced by soil conditions and vine nutrition prior to harvest is a major factor considered in nutrient applications made throughout the season. The pH falling somewhere between 3.0 and 4.0 is an important factor in the quality of grape juice, must, and overall final wine. Generally, white wines with a pH greater than 3.6 may be “flat” or “unbalanced” while wines with a pH near 4.0 will not age well and will be more prone to oxidation and microbial growth. There are several faults that can occur in wines as due to uncontrolled microbial growth as a result of an elevated pH. Wine pH is measured using a pH probe, and measurements should be taken prior to and after crushing and fermentation as the pH can change with each step in the winemaking process.

- Titratable Acidity – often abbreviated as TA, is a much better predictor of acid flavor (tartness) than pH. TA is determined by measuring the amount of a strong base such as sodium hydroxide required to neutralize the acid in the juice or wine to a known pH. Just as pH is important to the stability of the wine, TA is important to the flavor. A common issue when dealing with a high pH wine is that when the winemaker adds acid to the wine to lower the pH, the TA or tartness increases. With high pH wines, it is often not possible to acidify the wine enough to properly adjust the pH without raising TA to extremely high levels.

Sources of Variability

When purchasing grapes from a producer, winemakers desire uniformity of optimal ripened fruit across vineyard blocks at harvest. There are multiple factors that can cause variability in ripening and they all will have effects at different levels, from the vineyard block all the way down to the individual berries. So, understanding where this variability can occur is essential when sampling berries prior to harvest.

- Block – Differences in soil type across the same block can affect soil water infiltration rates causing differences in canopy size. Row orientation can also have an effect on the amount of sunlight received by the clusters.

- Individual vines – A non-uniform crop load across the vine can affect berry maturity at harvest time. Variable vine age from replants will also contribute to variability between individual vines.

- Clusters – Extreme differences in the number of clusters per vine and/or the density of the canopy can cause variability in grape ripeness. Also, physical damage to certain portions of the cluster as a result from hail can affect overall quality.

- Berries – Uneven sun exposure to clusters, poor fruit-set, damage from birds, disease or insect infestation can cause variability in the capability of the vine to ripen each individual berry on a particular cluster.

The ripening process of wine grapes in Texas is complex. It has many different moving parts, and all are influenced in a multitude of different ways by a variety of factors that change on a yearly basis. Every year as the grapes mature the berries undergo multiple changes both physically and chemically. However, this complex process can be accurately monitored with effective sampling techniques. Sampling adequate amounts of berries across specific areas, or varieties throughout the ripening process is an effective technique producers can use to track crop maturity and quality. Understanding what information these sampling techniques provide, and where variability can arise within this information is important for effective utilization. Maturing grapes for excellent wine quality in Texas is a challenge, and these tools and techniques can help, because after all great wine is made in the vineyard!

Daniel Hillin | Extension Viticulture Program Specialist

Texas A&M AgriLife Extension Service | 1102 E. Drew Street, Lubbock, Texas 79403

Phone: 806.723.8412

E-mail: daniel.hillin@ag.tamu.edu